To make the design look amazing on a wall rather than flat on a laptop, the trick is professional preparation. Poster printing provides no mercy: minor errors can become omnipresent at scale; careful file preparation ensures colors pop, type appears legible, and images remain sharp. It has taken a decade of assisting teams in getting files to all sorts of wide-format printers, ranging from shoot-and-shoot digital labs to gallery-quality gicl ee studios, but this is the process I follow to give you print-ready posters that exactly match what you saw on the screen.

The Importance of Preparation in Poster Printing

The posters can be seen at longer distances than the flyers but nearer to the billboards. The same middle area blows up problems such as soft photos, muddy blacks or reflowing fonts they were not embedded. Clarity, color accuracy, and consistency are the three aspects of good prep that matter the most. The right resolution and use of vectors provides clarity. The right color spaces and profiles yield color accuracy. Predictability is brought by a repeatable export workflow process which removes last minute surprises.

Begin with the End in Mind: Size, Orientation, and Viewing Distance

Put your completed size and where the poster will view in small notes before you even touch your design file. Conference hallway A1, a 24″x36″ shop window display or a 30″x40″ gallery print all have different finish and pantone resolution requirements. Pixels are determined by viewing distance: the nearer the viewers are, the more detail they will notice. Orientation influences composition and hierarchy, portrait is more fit to people and tall objects, landscape has more space to breathe to charts or expansive land.

Two commonsense principles are useful. One, design at full scale wherever you can because you don’t want to scale artifacts later. Second, if you find your app failing with large canvases, designed at half size and with twice the resolution and stick to all vector objects being really vector, so when you export everything remains sharp.

Resolution and Scaling: Real DPI/PPI Without the Myths

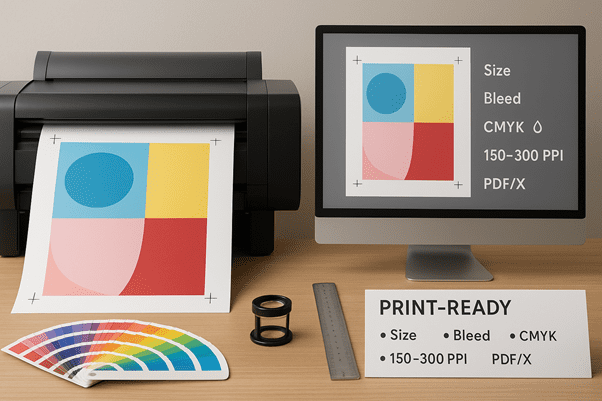

Regarding large-format poster printing, the 150-300 PPI at the print size should be the target to achieve with photographic conceptual content, where the higher range integration is needed only for reasonably, close viewing. Raster graphics in logo and type are to be avoided; leave that as the vector part. Should you need to increase an existing picture, do so early in the workflow, and check the outcome at 100% zoom on a calibrated display. De-noising prior to output-specific output-specific sharpening tends to be overwhelming upscaling.

A short cut that several teams have used: 200-300 PPI museum-style prints and in-store displays, 150-200 PPI event posters and classroom visuals, and really really large items to view many meters away at 100-150 PPI. When that picture appears soft when zoomed in 100 percent on the screen it will appear soft on paper.

CMYK, ICC Profiles, and Gamut Shifts – Color Management Print

Screens speak RGB; the majority of poster printers speak CMYK. An end-converter without the control of lights helps to dull reds, crush shadows, or make deep blues purple. Design in RGB to maintain flexibility and soft-proof as early as possible based on the output ICC profile based on which your print provider advises. Soft-proof with a generic coated stock profile and note them in advance about any color-sensitive brands.

In exporting, convert to CMYK (correct profile) and embed. In case you use the brand spot colors, retain them as a spot swatch unless the printer requires a CMYK build. In deep areas, very black should be substituted as opposed to 100 percent K to prevent charcoal. A typical coated stock build would be something like C60 M40 Y40 K100 although please ask your printer what they would like the build to be to suit their ink set and paper.

Survivable File Formats

PDF is the ruler of poster printing since it preserves vectors sharp, pre-embeds fonts, and flattens transparency reliably when optimized adequately. When applicable, use predictability by producing PDF/X specifications. High-bit TIFFs are fine on posters with photo only but mushroom in size and don t treat type with grace. Low-quality JPEG compression should be avoided, and JPEG, in general, should be exported at maximum quality with bare minimum artifacts. EPS remains in use with some vector workflows, but nowadays would typically be substituted with modern PDF.

Elements of Layout: Bleed, Safe Area and Trim

Posters get trimmed after printing. Add bleed To guard edges and prevent white slivers, always add bleed, or, minus in your printer setting specification, 0.125″ (3 mm) all around your art. Important information such as logos and small texts should be kept within a safe zone of at least 0.25″ (610 mm) away from the trim. Consider putting crop marks in it only when requested by the provider; most RIP workflows do this automatically.

Legible and Sharp Typography

Use heads in print with obvious tracking and never use too thin enough that the weight will break open on porous papers. Only when the fonts cannot be licensed or embedded, consider converting the live text to outlines; however, it should be recalled that outlined text cannot be edited. The legibility sweet spot in most-used distances of body text in posters begins about 18-24 pt, but measured with printed proof of size. Color contrast during watch facing: lighter text on mid tones rapidly disappears in any surrounding light, but darker text on lighter grounds can be used to understand it further away.

Images and Photos: Image Quality, Image Edit, and Output Sharpening

Begin with the best source image you can obtain. Optimize globally, exposure, white balance, color cast, and then locally, do some dodging and burning, to coerce the eye. The retouching ought to minimize the distractions, though natural when it comes to the textures. Last to last is the sharpening of the size of output and type of paper. Gloss and satin papers can be sharpened a bit more than can matte or uncoated stocks, which enhance grain and halos.

Transparency Flattening, Rich Blacks and Overprint

Solid black, big chunks should come out as rich black, not pure K. Push build to meet density/drying. Disengage overprint on items, except where you really mean it; spur-of-the-minute overprinting is an old bugbear in disappearances. It is required to flatten complex transparencies in your export settings when your printer requires it, particularly when using drop shadows, gradients, or spot colors together.

Finishes, Durability and Paper Stocks

The style alters more than just the design with your choice of stock. Posters with lots of photography get additional saturation and contrast on glossy papers. Satin or semi-gloss is a middle ground in that it minimizes glare without making colors dull. Matte and uncoated papers are recommended to use in type-oriented projects, fine art or where the light source is severe. When applied over a long period of display or in areas of heavy traffic thought should be given to using heavier weights, tough synthetic fabrics or applying protective laminate. When mounting on to foam board or some other rigid substrate, check final thickness and if you require bleed out beyond the edge of the mount.

Recognition of Problems Spelt out in Proofing and Preflight

Always ask them to show proof. Trim, bleed, and layout are checked by a digital soft proof. A proof at small scale is carried out in order to check typos and overall color balance. A complete section proof is not bad when it is important to have the tones of the skin or the colors of the brand or essential gradients precise. Preflight the file before sending: verify page size, bleed, color space, effective PPI on the images, embedded fonts, and spot colors. The preflight panels on many design apps kill machines, use it.

Popular Design App Export Settings

Adobe InDesign

Use the recommended final trim size and Document Setup in bleed size. Bond high-res images and retain type to vector. Export as PDF/X with printer marks and bleed according to request. Export to target CMYK profile and make that profile embedded.

Adobe Illustrator

Work full scale where possible. Enlarge the appearances of the complex effects, check overprints, keep text live and use embedded fonts. Export in PDF/X. In case the artboard is massive, think about a scaled work flow yet alert this to your printer.

Adobe Photoshop

Photoshop is most applicable in photo based posters. Start with the canvas at final size and resolution. Save a layered PSD in case of future edits, but export to a flattened TIFF or a PDF where necessary when there are elements of a vector type or shapes that are imported through Smart objects.

Other Cloud Tools, Canva

Design at the finished size. If possible, download a print PDF with bleed, and do not use heavy transparency or effects that will rasterize in an unpredictable way. When brand color-accuracy is mission-critical, pilot a sample run with a vendor, first; web tools usually lack extensive color-management controls.

An example of a Real-World workflow

A retail crew must have a 24 inch by 36 inch season poster, with a photo of the product, a Price, and a Headline. The process starts by a check of the size, orientation and viewing distance at approximately two meters. The product image comes as 6000X4000 which gives 166PPI at this distance a small print; this is acceptable in this case. Having color corrected the picture in RGB, we soft-proof the print machine CMYK profile and adjust the saturation to red’s gamut compression. The headline font is a bold sans at 180 pt with Lot of tracking; the price is cut at 120 pt and displayed pure white against a deep, thick-black gradient color. We also set a 0.125″ margin and ensure all the most essential parts are at least 0.25″ inside the cut and export a PDF/X with embedded profile. A press check on satin stock has crisp type and punchy color, final run is shipped the same day.

Most Frequent Errors Which Destroy Big Posters

- Where colors are often affected is the blind RGB design and conversion at the end.

- The provision of low resolution web graphics or rasterized logos will cause blurred edges.

- Bleeding leaves the thin slices of white when trimmed.

- They may disappear when line hairline strokes are used below 0.25 pt.

- Text that resorts to light font types to read at long distances cannot be legible.

- Reflowing can occur by exporting without embedding fonts, or outlining fonts.

- The worst thing that anyone can do is to skip proofs.

Post-Print Finishing: Lamination, Mounting and Handling

Completion adds longevity and increases display. There is a protective laminate against fingerprints, UV fade, scuffs-gloss to maximize photographs, matte to minimize glare. Presentations should mount the print potentially to foam core or gator board or aluminum composite to maintain print stiffness. When the poster is traveling, ask for corner protectors, flat packing and handling notes. Keep prints cool and dry and allow them to acclimatize before mounting, otherwise it will curl.

Eco-Friendly Poster Printing Options

Quality does not have to be compromised to be eco-smart. Use recycled or responsibly sourced papers, inquire into water-based inks, and size runs accordingly to minimize waste. The margins may be designed to be consistent and can enable GV impositions to be made guillotine-efficient, saving stock on multi-poster orders. In the case of short-term campaigns, you can put some lighter weights that consume less materials but still appear crisp when mounted.

Rapid Preparation List

- Insure final size, orientation and viewing distance

- Set document at 100% with 1/8″ (3 mm) bleed

- Critical content should be within a safe zone of at least 0.25″

- Have final size photos at 150 or 300 PPI

- Make logos and type vector; sunken fonts

- Soft-proof against the ICC profile of the printer and adjust

- When fills are large and dark, fill with rich black as recommended

- Export a PDF/X with embedded profile and preflighted files

- preproofing

CONCLUSION: A Duplicable System of Printable Posters

Outstanding large-format poster printing is not an accident. It is the result of a uniform expert procedure: establish the final size and context, design using the appropriate resolution and vector objects, consider the color consciously, create the bleed and margins, generate a preflighted print-ready PDF, and proof before printing the whole run. In that case you will make posters that will look as you first envisioned them, sharp when seen across the room, true in color in actual lights, and durable enough to do the job. The next time your art transfers off of the screen onto the wall, you will be prepared with a beautiful-printing-first-time file.

FAQs

How much resolution would I really require on a big poster?

The resolution at the printers size of final products of posters on paper should be 150-300 PPI in the majority of the cases. High PPI is required when the viewing is closer and less when viewing is distant. Keep type and logos a vector to ensure that they stay sharp at every size.

Which is better to design RGB or CMYK to print a poster?

Design RGB to keep flexibility and wide gamut unless you are working with a printer that needs a specific profile early soft-proof according to their ICC profile. Export as CMYK knowing that profile, and embed it or leave spot colors instead on brand-sensitive areas in case your vendor understands them.

Which file format do I send to the printer?

The safest one is a print-ready PDF, ideally through a PDF/X preset. It supports transparency, supports the embedding of fonts, and maintains vectors. Good TIFF are good enough to be used in purely photographic posters and unsatisfactory in non-pure-photo layouts.

Why were my blacks gray on the final print?

Pure K constructions at large coverage appear dull. Request a thick-black build that fits the stock and ink set. Under the suggested CMYK blend, darker and more homogeneous blacks are produced in the larger spaces.

Do I really require bleed in a poster?

Yes. Printed posters are subject to trimming, and bleed lets them accommodate some cutting allowances. Without it, you are vulnerable to white edges that surround your design.

What can I do so that even a tiny font will be legible at a distance?

Have adequate point size, distinct typeface with good x-height, wide tracking and intense contrast with color. Avoid super-thin fonts and do not put the text near crowded image sections. A scaled proof will allow you to proofread legibility.

Does it allow me to print a sharp poster based on a phone photo?

Sometimes. Current phones record in high resolution, though noise and excessive sharpening may appear at high sizes. Zoom into the file 100 percent, reduce noise and sharpen according to output. Is it still marginal-looking? Remember the smaller size or the limitation-shielding design.

What is a good finishing option on retail posters?

Under store lighting, Satin or semi-gloss is used to balance the color intensity with less glare. Consider putting a layer of protective laminate on the poster to avoid frequent manipulations or more extended periods of use.